In the fast-paced world of industrial manufacturing, efficiency and accuracy are critical, especially when dealing with small components like fasteners (screws, bolts, nuts, etc.). Counting these items one by one is impractical for large-scale operations, which is why weigh/counters have become essential tools. In this blog, we’ll dive into how a weigh/counter works with industrial fasteners, spotlight the Batching Systems Inc. Fast Automatic Weigher (FAW), and compare it to a traditional pan feed weighing system. Weigh counters for industrial fasteners are essential in achieving both speed and precision in modern manufacturing.

What is a Weigh/Counter for Industrial Fasteners?

A weigh/counter is a machine that combines weighing and counting into one streamlined process. Instead of manually tallying each fastener, it measures the total weight of a batch and calculates the number of pieces based on the known weight of a single fastener. This approach is ideal for industrial fasteners, which are often uniform in size and weight, allowing for quick and accurate batching without the tedium of individual counting.

How Does Batching Systems Inc. Fast Automatic Weigher (FAW) Work?

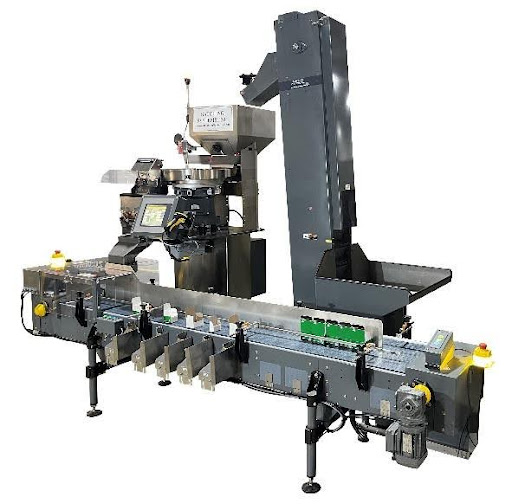

The Batching Systems Inc. Fast Automatic Weigher (FAW) is a standout example of modern weigh/counter technology tailored for industrial fasteners. Here’s a breakdown of the different components and how it operates:

- Vibratory Feeder: Fasteners are introduced into the system through a vibratory feeder, which ensures a consistent flow of product fed out of the Bowl Feeder or Tray feeders for larger volume batches.

-

Weighing and Counting: The FAW uses a single accumulation bucket with dual gates. 1 accept gate and 1 reject gate. A built-in weight-to-piece converter then calculates the exact count by dividing the total weight by the average weight of one fastener.

Overweight batches are rejected into a reject bin or return conveyor.

Patented Technology: The FAW boasts several innovative features:

- Dual Chamber Product Accumulation: This allows continuous operation by storing fasteners in two chambers, keeping the process moving smoothly.

- Dual Output Bulk-Fine Feeder Bowl: The system starts with a bulk feed to quickly approach the target weight, then switches to a fine feed for precision.

- To-the-Piece Batch Top Off: This ensures the batch reaches the exact count, even adding individual pieces if needed.

- Out of Tolerance Batch Reject: Any batch that doesn’t meet the specified weight or count is automatically rejected, maintaining quality control.

- Automation: The FAW adjusts the feed rate in real-time to hit the desired batch weight or count. It can operate semi-automatically or integrate into fully automated production lines, complete with storable setups, self-diagnostics, and remote monitoring capabilities.

Why the FAW Shines for Industrial Fasteners

The FAW is purpose-built for hard goods like fasteners, offering:

Efficiency Continuous feeding and weighing cut down processing time.

Precision Patented technologies ensure every batch meets exact specifications.

Versatility Works in both semi-automatic and fully automated setups. No tools are required for different product sizes and shapes.

Quality Assurance Rejects off-spec batches, guaranteeing consistency. Heavy duty construction with few ware parts will provide decades of reliability. Backwards compatible electronics provide a future piece of mind with maximum uptime.

For manufacturers handling large quantities of fasteners, these benefits translate to faster production and fewer headaches.

Efficiency Continuous feeding and weighing cut down processing time.

Precision Patented technologies ensure every batch meets exact specifications.

Versatility Works in both semi-automatic and fully automated setups. No tools are required for different product sizes and shapes.

Quality Assurance Rejects off-spec batches, guaranteeing consistency. Heavy duty construction with few ware parts will provide decades of reliability. Backwards compatible electronics provide a future piece of mind with maximum uptime.

For manufacturers handling large quantities of fasteners, these benefits translate to faster production and fewer headaches.

Conventional Pan Feed Weighing System

The FAW takes raw fasteners, weighs them accurately, and delivers precise batches—all with minimal human intervention. To appreciate the FAW’s capabilities, let’s compare it to a conventional pan feed weighing system:

Process - Fasteners are fed into an accumulation bucket out of a tray. In most cases the system does not have an independent top off tray and just slows down the feed rate to hit the target weight. Overcounts are not rejected and can only be accepted. Tray feeders require a lot of products to run efficiently. Unlike bowl feeders that can run a small or large amount of product.

Process - Fasteners are fed into an accumulation bucket out of a tray. In most cases the system does not have an independent top off tray and just slows down the feed rate to hit the target weight. Overcounts are not rejected and can only be accepted. Tray feeders require a lot of products to run efficiently. Unlike bowl feeders that can run a small or large amount of product.

Drawbacks:

-

Manual Effort: Requires significant operator involvement, slowing down the process. At times operators might have to reweigh the batch and add/remove the product.

-

Error-Prone: No fine feed and No reject can lead to miscounts or inconsistent batches.

-

Speed: Best suited for smaller batches, as larger quantities amplify the time and effort needed.

Advantages:

-

Process: Fully automated feeding, weighing, and counting with advanced controls.

-

Automation: Eliminates most manual tasks, letting the machine handle the heavy lifting. Easily integrated with other equipment, baggers, box lines, jar lines, clam shell lines.

-

Speed and Accuracy: Features like the bulk-fine feeder and continuous operation enable fast, precise batching—ideal for high-count fastener batches.

-

Error Reduction: The out-of-tolerance reject feature ensures only accurate batches proceed.

-

Advanced Features: Dual chamber accumulation and remote diagnostics enhance efficiency and reliability. Product versatility with toolless change over. Small footprint with high-speed production.

While a pan feed system might suffice for low-volume or simple tasks, the FAW excels in high-speed, high-accuracy environments where industrial fasteners are processed in bulk.

Conclusion

When batching industrial fasteners, the difference between a conventional pan feed weighing system and the Batching Systems Inc. Fast Automatic Weigher is night and day. The FAW’s automation, speed, and precision make it a game-changer for industries needing reliable, high-volume batching. If you’re looking to streamline your fastener handling process, the FAW is a top-tier solution that leaves traditional methods in the dust.